Welcome to Hotel Marcel—the largest Passive House-certified hotel in the country, it operates fully on renewable energy, without any use of fossil fuels.

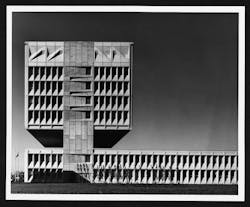

Originally designed by Marcel Breuer for the Armstrong Rubber Company’s New Haven, Conn., headquarters, the 1960s Brutalist structure consists of a floating concrete box with deeply recessed windows. The historic building sat abandoned for years until architect Bruce Redman Becker decided to purchase it and turn it into a highly sustainable boutique hotel.

Passive House certification, managed by Passive House Institute (PHI), is the only internationally recognized performance standard for air tightness and energy consumption, verified with field-tested energy modeling. Over 5,600 buildings in the world have earned Passive House certification, of which only 140 are in the United States. Hotel Marcel is the first hotel with over 100 rooms to be certified in the world. The project is also one of the few LEED Platinum-certified hotels in the country.

Achieving this top-tier level of energy performance, in an existing 1960s building, has generated a lot of interest. “Two major hotel chains have sent their top engineering and sustainability leadership to Hotel Marcel with hopes of replicating our successful efforts and two other hotel groups have engaged me as a consultant to decarbonize their portfolios,” reports Bruce Redman Becker, FAIA, PHCD, LEED AP, Becker + Becker. Westport, Conn.

While Becker’s undertaking of a Passive House renovation was ambitious, a number of the building’s qualities made it a good candidate for the transformation. For example, the simple, box-shaped structure was easier to insulate and condition than others. The ultra-high-performance concrete offered thermal insulating mass and the Mosai-style concrete panels, with windows inset a full 30 inches from the façade, provided excellent passive shading.

Tighten the Building Envelope

Tightening the building envelope was a key strategy for achieving Passive House performance criteria. “The pre-cast MoSai concrete panels were air-sealed and coated with high-performance insulation on their concealed interior surface, and air-sealing tapes and Aerogel blanketing were used to complete the thermal isolation of the windows without adding thickness to the original wall assembly,” explains Becker.

The original windows were replaced with triple-glazed, argon-filled, laminated windows. In addition to the insulation, the windows also act as acoustic dampeners which is key as the hotel sits close to I-95.

Maximize the Use of Daylight

“In its reincarnation, the building embraces sunlight—capturing its energy with over 1,000 PV panels on the roof and on exterior canopies—and distributing more daylight to the interior with the creation of two light wells and the transformation of former mechanical spaces into open-air courtyards,” says Becker. “New interior glazing, where the building’s cooling towers once stood, allows light to flood the new meeting spaces on the 9th floor where the massive trusses are now architectural features of the meeting and conference spaces.”

The rooftop is outfitted with 360-watt SunPower PV panels with SMA STP Core1 62.5 kW inverters and the carport houses 470-wattSunPower units with both the SMA STP Core1 62.5 kW and 33.3 kW inverters.

Select High-Efficiency, Electrified HVAC and ERV Systems

To achieve Becker’s aggressive net zero energy and Passive House goals, high-efficiency HVAC systems and energy recovery ventilation (ERV) were essential strategies to drive energy costs way down.

The hotel has two variable refrigerant flow (VRF) systems. One for space heating and cooling and another for hot water.

Delivering both heating and cooling are multiple Mitsubishi VRF air-source heat pump systems with fans, compressors, refrigerant coils, and controls within an outdoor condensing unit in addition to interior fan coil units and branch selector boxes.

“We considered a Watts system, but chose Mitsubishi based on pricing and availability. It was the most cost-effective option to provide the end result,” stated Aaron Kruger, project manager, Consigli Construction, Manchester, Conn., in an Urban Green Council presentation on Energy Upgrades in Historic Buildings.

By utilizing the refrigeration cycle, the VRF heat pumps can exchange heat energy between the outdoor ambient air and the interior air. “These systems have a Coefficient of Performance (COP) of approximately 3.5 at 47 degrees F outdoor air temperatures, which is about 350% more efficient than an electric resistance heater,” reports LN Mechanical Engineer and Project Manager Ian Donohue, P.E.

The VRF systems’ simultaneous heating and cooling capabilities means that the equipment can both heat or cool individual zones at the same time and that cooling mode spaces can share their heat energy with areas in heating mode for enhanced energy savings.

Another benefit is the system’s use of a natural refrigerant that has a Global Warming Potential (GWP) value of 1, compared to typical refrigerants such as R-134a and R-410a which have GWP values of 1,430 and 2,088, respectively.

While the Heat20 all-electric heat pump water heater is the primary source of domestic hot water production, backup/supplemental heating for the domestic water is provided by electric resistance water heaters.

For the Swegon Energy Recovery Ventilators, the system exchanges both heat and moisture energy between the outgoing exhaust air streams with the incoming outdoor air. Highly efficient, the system is capable of reducing the energy needed to condition the ventilation air by approximately 80%.

“The incoming ventilation air is filtered by high-efficiency MERV-13-rated filters which reduces the quantity of airborne pollutants. Post-conditioning of the ventilation air to approximately 55 degrees supports dehumidification, reducing the indoor space humidity levels when required,” said Donohue.

Another energy-saving feature is Variable Air Volume (VAV) boxes which meter the amount of ventilation air provided to and extracted from each individual ventilation zone. By monitoring CO2 levels, the ventilation air flows can be reduced during periods of low occupancy.

Another first for a large hotel was electrifying the kitchen. This involved the use of induction ranges and recirculating Type 1 grease-laden, vapor-rated exhaust hoods. “The hoods utilize a self-contained 4-stage filtration process to reduce emissions which includes a high-efficiency filter/carbon-charcoal filter pack. This enabled the ERV to provide ventilation air to the kitchen rather than installing a dedicated make-up air system” explains Donohue.

PoE Lighting and Shading

Another unique aspect of the electric design is the use of Power over Ethernet (PoE) lighting and shading systems, designed and installed by Sinclair Digital.

“PoE lighting allowed us to ‘gut’ the existing fixtures and use LED lights without having to buy new LED drivers. This allowed the voltage levels for all the lighting to be in the 24-volt to 48-volt range,” explains John Askew, P.E., principal, LN Consulting, Burlington, Vt. “PoE lighting also allows the ‘power’ cable to be the ‘control’ cable, reducing wiring since now only one cable needs to be run. It also made running circuits less expensive since conduit or metal-clad cable is not required at these lower voltage levels.”

Another reason for PoE lighting was the project’s use of digital energy transmission systems. The Voltserver takes 120-volt or 277-volt AC power and converts it into ‘digital energy’ which is sent to a receiver that converts it to a usable voltage, in this case 24 volts. This then negates the need for higher voltage AC power for lighting.

More than 900 automated roller window shades with PoE technology from PowerShades were installed at Hotel Marcel. As the industry’s first and only PoE automated shade system, a single CAT5 cable provides both power and communications, so no proprietary hard wiring is needed. Further, the motor is low voltage and doesn’t require a licensed electrician for installation.

“New hardwood window surrounds follow the geometry of the original angled plaster sills and jambs, and incorporate a shade pocket for the window shades,” Becker explains.

Realizing a Microgrid Scheme

Overall, the mechanical and electrical engineers had to contend with the formidable challenge of converting the design of an existing building with gas and electric equipment and no alternative energy sources into one with all electric systems and the integration of a battery energy storage system (BESS).

A battery energy storage system enables energy from renewables, like solar and wind, to be stored and released when the power is needed. In the case of Hotel Marcel, it allows the hotel to be powered by green energy, even when the PV panels aren’t actively capturing solar energy—at night or on overcast days. Energy can also be released from the battery storage system during times of peak demand, keeping energy costs down and electricity flowing.

“Coordinating the BESS with the photovoltaic system and utility power supplies, the system started to get complicated,” said Askew.

While PV and BESS systems are not new, very few facilities have attempted to implement a microgrid scheme which was needed for load shedding, peak shaving, battery charging, off-grid use, and synchronization with the utility.

“The project actually had to go through two microgrid control system designers to find one that could implement what the design team was trying to do,” he adds.

In addition, the team had to work closely with the local AHJ for approvals as the relevant building codes were vague as to what was allowed.

Energy modeling demonstrated energy cost savings over the ASHRAE baseline system of approximately 80%.

When asked about the investment required for the highly sustainable conversion Becker explains that several incentives made the project less expensive than new construction. He lists a 30% federal solar and battery tax credit, a 20% federal historic tax credit, as well as a state historic tax credit, CPACE financing, and utility grants. In addition, the lowered overall utility bill will pay out dividends over the building’s lifetime, making the Hotel Marcel a good investment for decades to come.